Hypnos Bed Factory Mattress Production

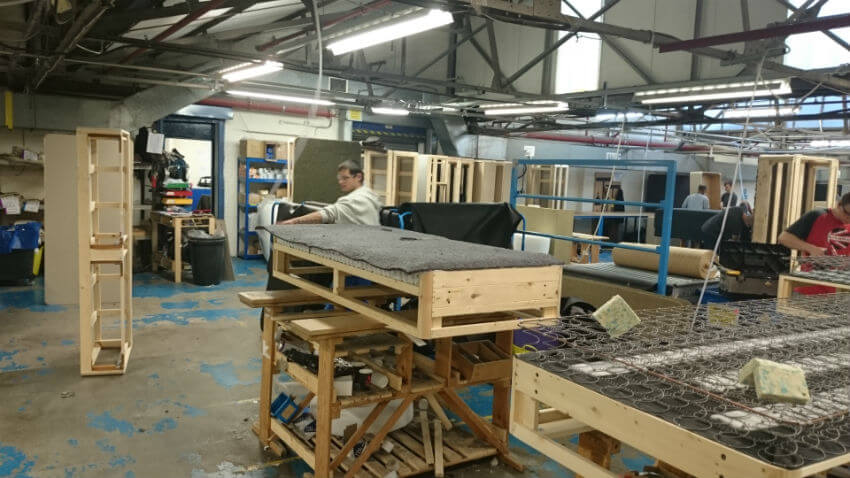

Today we visited the Hypnos bed and mattress factory at Princes Risborough. It was a very interesting day and as well as visiting the showrooms, we got a guided tour of the factory and saw how their mattress and divan bases are made

Hypnos Mattress manufacturing process

Below are pictures of the various manufacturing stages of a Hypnos mattress.

Hypnos Bed Factory - Princes Risborough

Hypnos Preparing Springs

There are approximately 70 different springs used in the production of Hypnos mattresses and Hypnos beds. Once the pocket springs are nested into shape, a rigid bar is clipped around the perimeter to hold the pocket springs together and maintain the mattress’s shape.

Hand Side Stitching the Border to the Springs

Heavy duty fabric handles are flag stitched to the border to aid rotation and turning. The air vents in the border of the mattress help to keep the interior ventilated. Depressing the mattress helps expel old air and any potential stale odours. Like the handles, the vents are fitted to all 4 sides of the mattress to provide the best possible airflow, without affecting the performance of the mattress.

Hypnos mattresses are hand side stitched. This is a process whereby a highly trained craftsman inserts a long upholstery needle with high tensile twine through the mattress border into the springs and the layers of fillings. This process ensures the fillings and pocket springs remain in place and the mattress border is firm and supportive. They use a minimum of 2 rows of hand side stitching. Mattresses like the Hypnos Adagio Supreme and Orthos Elite Cashmere have 3 rows of hand side stitching. Do not confuse machine side stitching which is purely visual with hand side stitching. Hypnos luxury mattresses have hand side stitching. Hand side stitching is a real skill learnt over many years. A specialist 2 ended 30 cm needle is used by Hypnos craftsmen to hand side stitch a number of rows at set intervals, creating a series of characteristic squares - the greater the number of rows the stronger the mattress will be.

Adding the Fillings

Hypnos mattresses then have generous layers of the finest natural fillings placed over the spring unit. In some cases these can be in excess of 12” of fillings. The fillings are then covered with a cover, called a tick, which is a tightly woven fabric. It is generally a high quality Belgium damask.

Tape Edging the Cover to the Border

Although a machine is used to tape edge a Hypnos mattress, the operative still requires great skill and strength to pull the mattress together.

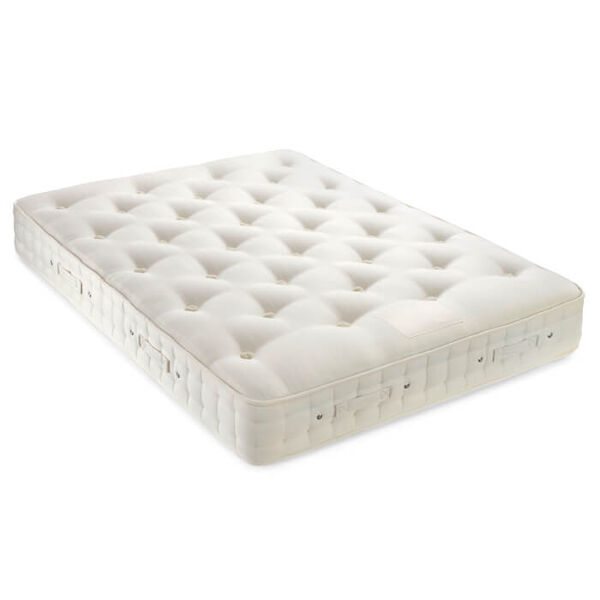

Completed Orthocare 8 Mattress awaiting Tufting

The Hypnos Orthocare 8 mattress is a no turn easy care mattress available in a firm or extra firm tension.

Tufting Rack

The Mattress is Compressed for Tufting

Once the mattresses are side stitched, the second finishing touch starts, the tufting. The pocket sprung mattress is placed in a press and compressed. A long tufting needle with twine is inserted through the mattress. On each end of the twine a tuft of wool or felt is attached. This makes sure that all the fillings stay in place and improves the life of your Hypnos mattress. Hey presto, the finishing touches complete the mattress.

Once the tufting process has been completed the mattress is sent of for final inspection prior to being wrapped and sent to the loading bay for onward delivery.

Hypnos divan base manufacturing process

All Hypnos divan bases are made from Scandinavian pine which is carefully checked for knots and defects. Hypnos will not accept a piece of timber that has 2 knots that are a third of the width of it within a 1 metre section. Scandinavnian pine is used as there is a continuous growing season so the timber is not prone to splitting.

There are a wide variety of Hypnos divan bases to choose from. Traditional deep divans are available with a platform top for firmer feel or a firm edge open coil divan base or a firm edge pocket divan base. Added to this are the shallow divan bed on legs, ottoman beds and the exclusive Hypnos Hideaway

Below are pictures of some of the manufacturing stages of a Hypnos divan base.

Sprung Edge Divan Base having the open coil springs attached

The spring edge base was discontinued at the end of 2020 in favour of the firm edge sprung bases. Sprung edge divan bases have been discontinued by many of our suppliers including Dunlopillo, Relyon and Sealy.

Firm Edge Base. One half of a 180cm linked base

Firm Edge Base Covered in Denim (recycled Jeans)

Upholstering the Base

Drawer Support to enable drawers to hold 28kgs

Before you leave, if you found this article helpful would you mind sharing to your social media profiles. Thank you

Come and visit our bed shop in Burgess Hill, West Sussex to try out or range of Hypnos beds and Hypnos mattresses. Click here to get directions to our bed shop on Google maps

Factory visit 24.11.2015